Manufacturing as Foreign Policy for India: India’s Industrial Strategy in 2026

Feb 6, 2026

India’s manufacturing narrative in 2026 can no longer be described purely in economic terms. It now influences how governments, companies and investors perceive the country’s role in global supply chains. Manufacturing remains a relatively small part of the economy — contributing around 12 to 13 percent of GDP — and India’s share of global manufacturing output is under three percent, compared with China’s share above 25 percent. Yet certain segments, especially electronics, have demonstrated scale and competitive momentum. Electronics exports have exceeded $30 billion in recent years, and India has emerged as one of the world’s largest mobile phone manufacturing hubs.

The focus now should be on strategy rather than statistics. Indian manufacturing must aim for quality, connectivity and geopolitical relevance.

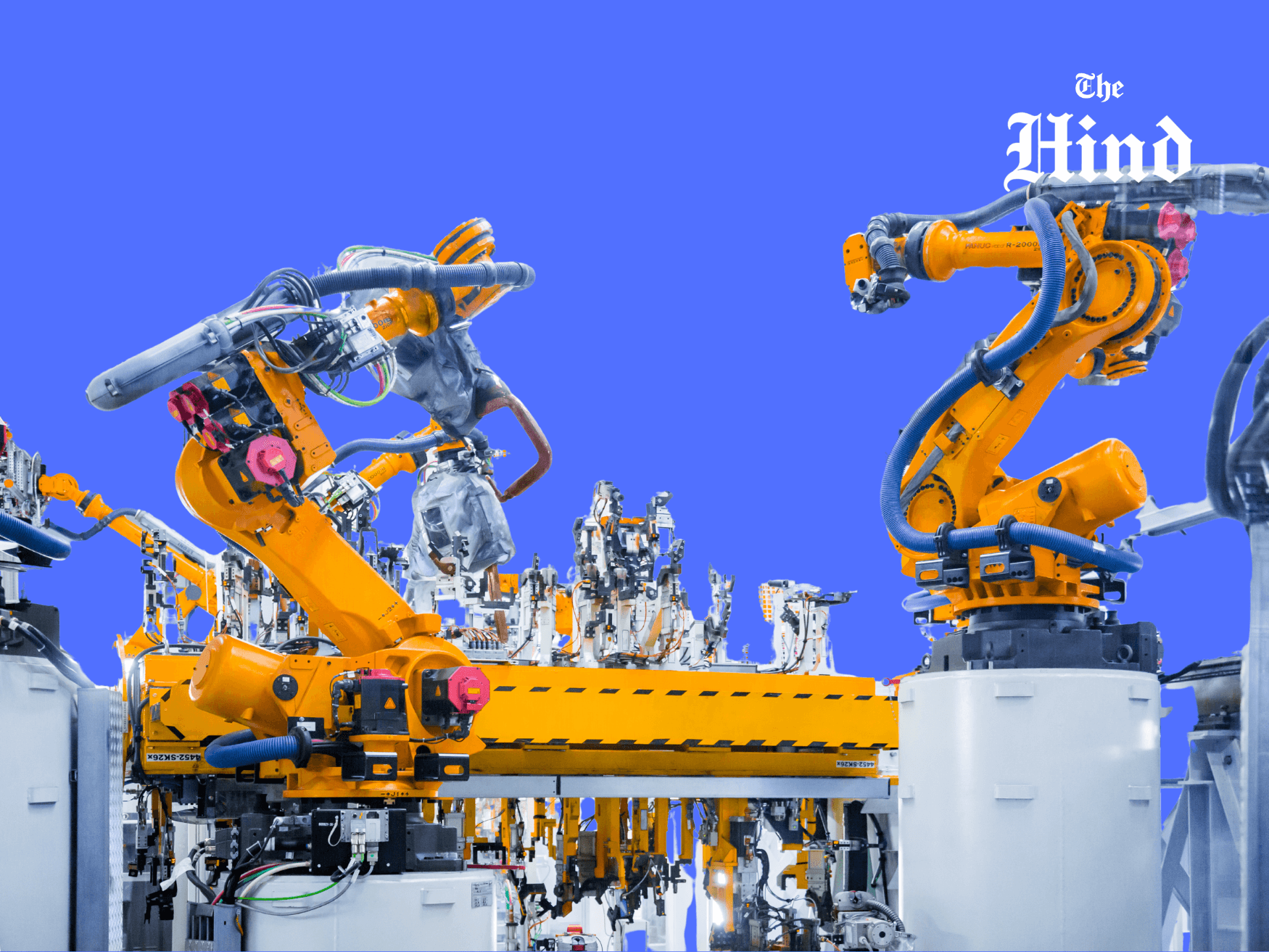

1. Develop Capabilities Beyond Assembly

India’s electronics sector has grown rapidly, driven in part by local production of mobile phones and consumer electronics. However, much of this growth remains concentrated in final assembly. To strengthen global competitiveness, India must build capabilities in critical upstream areas such as semiconductor packaging, electronics design, precision components and advanced materials.

Strengthening these segments will reduce dependence on imports and increase India’s bargaining power in global value chains.

2. Shift From Incentives to Core Competitiveness

Production Linked Incentive schemes have attracted investment and boosted output in priority sectors. As these programmes mature, the emphasis should shift toward core competitiveness — stable regulations, efficient logistics, reliable power, simplified compliance and easier access to capital.

Long-term industrial growth will depend more on how easily businesses can operate and innovate than on short-term incentives.

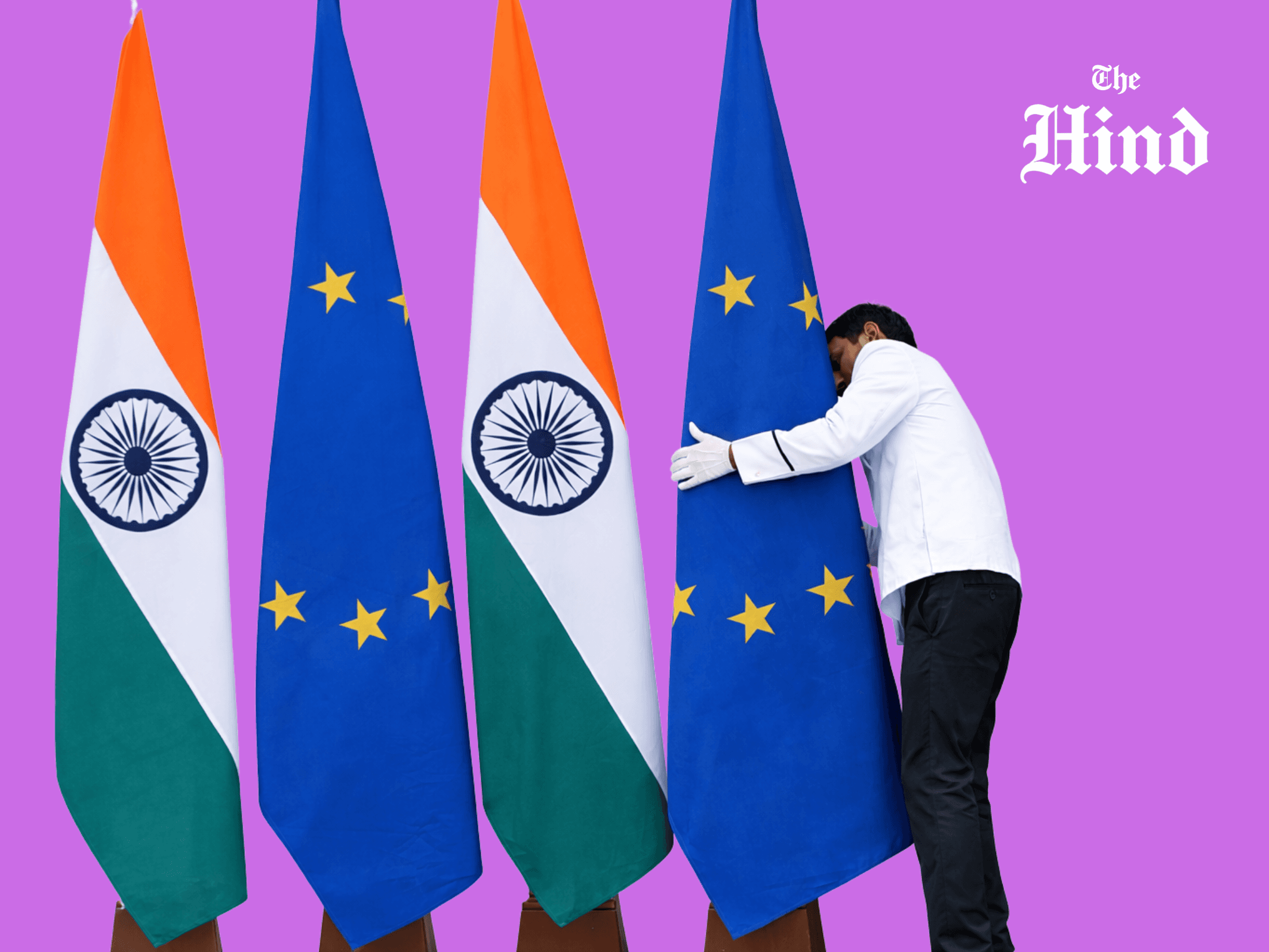

3. Elevate Manufacturing in Economic Diplomacy

Manufacturing outcomes now matter in trade and investment negotiations. India must strengthen its presence in economic diplomacy by placing industry specialists in diplomatic missions, coordinating state-level investment promotion with national strategy, and integrating production priorities into trade agreements.

Manufacturing should be presented not only as a destination for investment but as a partner in building resilient supply chains for other countries.

4. Cultivate Regional Industrial Strengths

States such as Tamil Nadu, Gujarat, Karnataka and Uttar Pradesh are carving out distinct industrial identities, with clusters in automotive components, chemicals, electronics and advanced materials. These regional ecosystems are becoming the backbone of India’s manufacturing recovery.

National industrial strategy should support these differentiated strengths with targeted infrastructure, accelerated approvals and specialized skill development programmes.

5. Modernize MSMEs for Global Participation

Micro, small and medium enterprises contribute a large share of manufacturing output and exports, and they employ millions across the country. Modernizing these firms — through access to digital tools, quality standards, finance and global market linkages — will generate deeper participation in global value chains.

Stronger MSMEs will create a broader base of suppliers for multinational companies and reinforce industrial resilience.

6. Align Skills and R&D With Future Needs

India’s demographic profile offers a large workforce. To translate this into industrial advantage, vocational training, engineering education and applied research must align with real manufacturing needs. Advanced technologies like automation, robotics and precision engineering require specialized training and innovation ecosystems.

Investment in these areas will ensure that Indian manufacturing moves up the value chain rather than remaining in low-skill segments.

7. Invest in Hard Infrastructure That Matters

Manufacturing competitiveness depends on efficient logistics, port capacity, reliable electricity and transport networks. Improving these areas will reduce costs and delays that currently hamper industrial activity.

Developing industrial corridors and export hubs with world-class infrastructure will enhance India’s attractiveness to global manufacturers.

The Strategic Stakes for 2026

Manufacturing today is not just about economic growth. It shapes diplomatic credibility, supply-chain partnerships and long-term investment flows. India now has visible momentum in certain sectors, particularly electronics and mobile production. But the country still lags many competitors in terms of global share and depth of industrial capability.

The opportunity ahead lies in turning scale into substance. Deeper value chains, stronger skills, clear regulatory frameworks and infrastructure investment are essential components of a strategy that makes manufacturing a durable source of economic strength and geopolitical influence.

In 2026, the factory floor is no longer simply a production site. It is a strategic platform on which India can build economic resilience and international standing.

Type something …

Search